Do operating conditions impact on design?

For manufacturers who implement LEAN practises. Losses such as waste and downtime are quickly highlighted.

When harsh operating conditions have not been considered, or older equipment is being used, failure is often an inevitable regular occurrence. Breakdowns are not acceptable for any manufacturer.

Outcomes

Fewer interruptions

Precise, accurate and reliable operation

Improved OEE

Increased profits and better quality products

Yes, it’s critical to consider the operating conditions for any machinery.

Technical Details:

Lean manufacturing practices are highlighting where there is potential for organisations to improve output, reliability, quality of product which in turn can deliver increased profits.

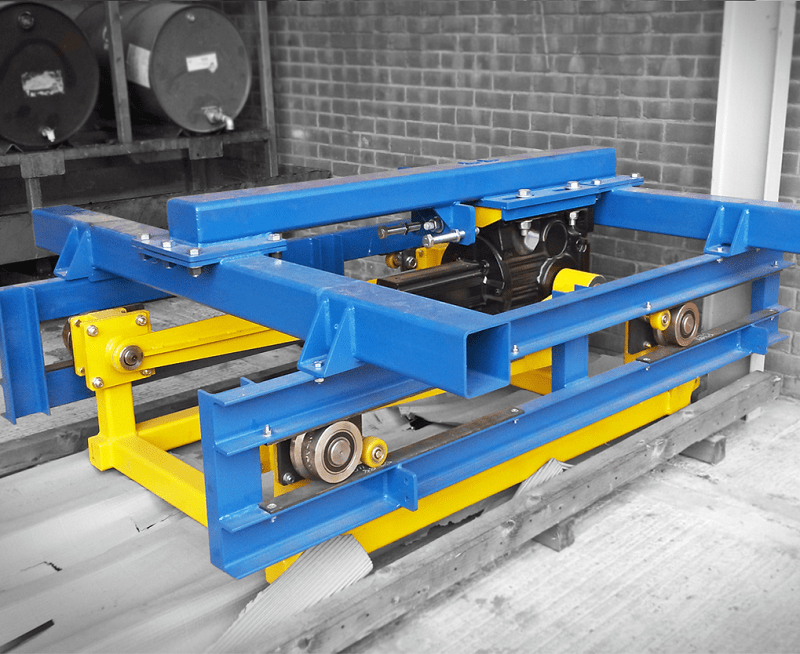

This client’s 25-year-old machine used hydraulics and sensors that often failed due to the harsh working environment. The new machine had to be installed and mirror the existing to prove that it would function correctly before switch-over. The servo drive accurately follows the rest of the machine to ensure everything is correctly synchronised.

What the client received:

A simple, robust, servo driven mechanical system was designed and installed in place of the original unit which could cope with high dust levels. The system was designed to be easy and simple to maintain.

Careful measurements revealed that a solution could be found where the new machine would be installed in such a way that met the client’s requirements and be better protected from the environment than the original. All components can be accessed for cleaning, inspection and if necessary, replacement.