The June Engineering Echo

We’re halfway through the calendar year and it’s been an interesting one hasn’t it?

For June’s engineering echo here’s the news from inside Bennett Engineering and some from outside too!

Bespoke Machinery

This month we’ve manufactured and assembled two machines for a VIP client of ours; they’d invested with an OEM but the machines just wouldn’t do what they were supposed. And no manufactured needs that situation on their processing line. So the team visited us at Unit 5 to discuss the design of machinery for two different types of machinery for the same line. Often the commercial thought process is that bespoke is too expense and OEM’s have the right kit. In our experience bespoke provides you with machinery that’s:

☑️ Designed and built specifically for your process

☑️ Designed and built specifically for your workplace

☑️ Easy to install and commission

☑️ Reliable and easy to maintain

We chose the industrial unit route for Bennett Engineering to be able to provide the entire turnkey solution from concept design to detailed design, bill of materials, manufacture and assembly. And the feedback so far from operators, engineering team members and management is that our machines are doing the job perfectly.

Factory in a box on show

Craig and Seleena were invited to an AI in Manufacturing event held at the impressive MTC facilities.

One of the showcases was an impressive factory in a box; essentially a processing line that fits into a shipping container. What the MTC team had delivered was a digital copy (not quite a twin) where maintenance could be done from anywhere in the world; or instructed to any operator using the factory in a box from the expert engineers who are unlikely to be anywhere close to them.

We reflected with pride on the two processing lines that we’ve designed and delivered to a customer whereby the line is within a shipping container which can be transported to anywhere in the world to the stockpiles of items that the line breaks into constituent parts ready for recycling. Whilst we didn’t do anything snazzy with digital twins or AI we did deliver an outstanding design for both lines that were improvements on the prototypes the customer had but were too expensive to commercialise. Now there are factory in boxes working across the world to recycle an often disposed of household item that holds valuable materials that can be recycled if sorted carefully.

PS Craig said last time he visited MTC lots of things were in boxes and this time was the same due to some significant investment plans being executed. Maybe next time we visit he’ll see it in all it’s glory as it’s truly an impressive space.

Have you heard?

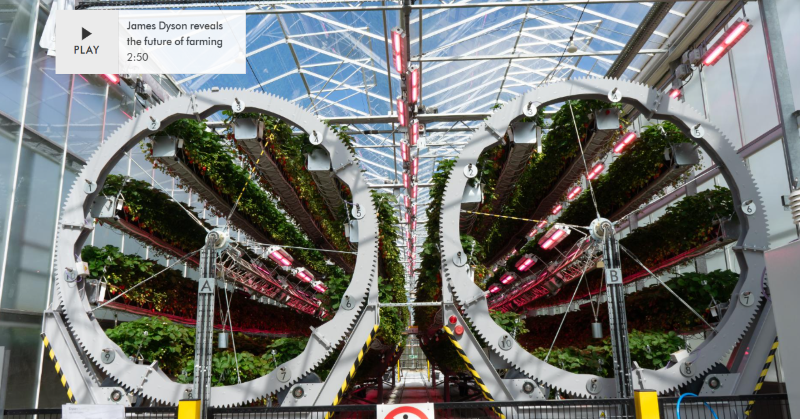

Dyson have moved into farming! More specifically strawberry farming. And it’s impressive.

Having worked on a Dyson project ourselves some years ago we understand the innovations and engineering thinking that goes into their projects.

‘Dyson Farming’s 26-acre glasshouse in Lincolnshire is already home to 1,225,000 strawberry plants, which are grown all year round, to produce over 1,250 tonnes of high-quality British strawberries.’

That means Britain could soon supply strawberries all year removing our reliance on imports with us liking to have access to the luscious red soft fruits any time of the year and not just during Wimbledon.

Have a look at the project here Dyson engineers boost strawberry yields by 250% in technology breakthrough

The industrial strategy has landed

Seleena has long been following a brilliant campaigner for an industrial strategy to be put in place who advocates on LinkedIn. This lady runs an SME and is very pleased with the recently released 10 year strategy (in the main anyway – she’d still like us SMEs to have a bigger voice!).

The UK’s Industrial Strategy marks a major commitment to revitalising British industry through innovation, sustainability, and skills development. Central to the strategy are increased investments in advanced manufacturing, clean energy technologies, and R&D, particularly in sectors such as aerospace, automotive, life sciences, and digital engineering. It outlines support for supply chain resilience, the scaling of emerging technologies like AI and robotics, and a renewed focus on regional growth through industrial clusters. The strategy also sets out a clear pathway to achieving net-zero goals, with incentives for decarbonising manufacturing processes and improving energy efficiency. With a strong emphasis on public-private collaboration, the strategy aims to create a more productive, future-proof industrial base that can compete globally.

We like this summary of what the strategy will deliver and are looking forward to the UK’s impressive manufacturing sector getting back on it’s feet and doing what it does best – making high quality things!

Come for a cuppa (or a coffee!)

The kettle is always on at Unit 5, if you’d like to come over to discuss business or a project please get in touch with Seleena (seleenac@beneng.co.uk or 01332 419220); who is probably better at making coffee than tea but will happily make you whatever beverage that makes you happy. It’s always a privilege to welcome people into our workshop area and then take you to the lofty heights of our design office and meeting space.

Our services include: