The August Engineering Echo Newsletter

This summer month is always a quiet one, if you’ve had a summer shutdown we hope all went well with the tasks you’ve completed within your factory. Or if you’ve taken some quality time out with family and friend we hope you’re refreshed and ready for the coming months (we are!).

Here’s some news and updates from the Bennett Engineering team.

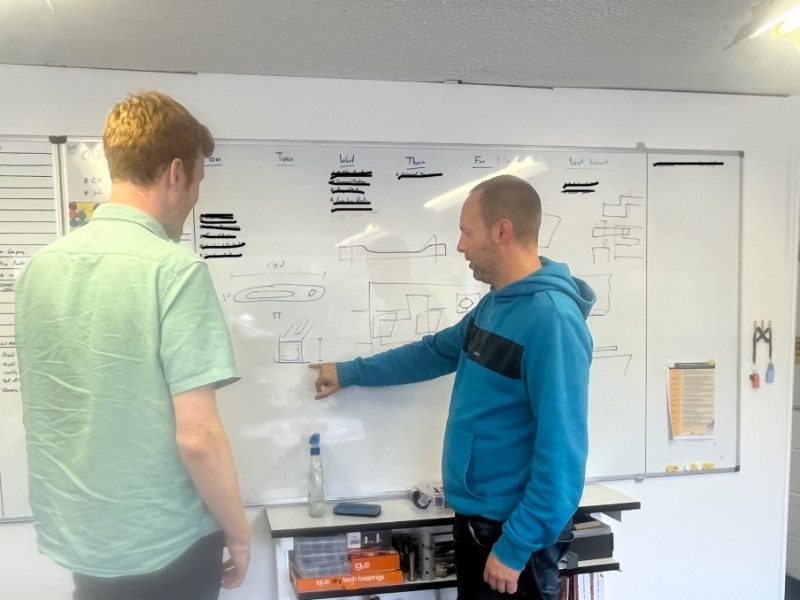

Bespoke is best!

We might be biased BUT we truly believe that bespoke machinery is the best option for some of the processes that are completed by manufacturers in various sectors.

Why?

Simple. The bespoke machinery that Bennett Engineering designs, manufactures, assembles and sometimes installs works.

There’s a statistic we like to share because we’re really proud of it and it’s this:

95% of everything that Bennett Engineering has designed over the last 12+ years has been manufactured and more importantly made a positive impact when used / made.

In the picture of bespoke machinery above the impact has been really positive for the building product manufacturer; their quality has increased MASSIVELY and their throughput is now where it should be for the factory.

We listened, we created the concept, we created the detailed design, manufacturing pack and BOMs then made and assembled the machinery (4 in total) and supplied them into the engineering team to easily install.

That’s a result we’re truly proud of.

Truly the Greatest Gathering

Craig managed to secure tickets to the Rail 200 Greatest Gathering here in Derby earlier in August.

Based at the Alstom site, where they are still manufacturing trains, the journey of railway was all there. To see the innovation in engineering from steam to the current trains (including Hydrogen fueled ones) was truly inspiring.

The one that Craig wanted to spend time seeing was ‘Locomotive Number One’ which was manufactured in the early 1800s. He said “it was a privilege to see this loco in person, I was so impressed with the train because it’s the start of the rail journey that’s based on engineers who solved a challenge and did it well.”

CNC machine in action

This year we invested in a small CNC machine, and Eddie (our summer intern) has been busy commissioning and creating on it.

The reason behind our investment was for the ‘smaller’ things we need to create as part of a larger bespoke project. But also to create some prototypes in more sustainable materials (like wood) that enable us to test design concepts.

And finally we wanted to support a Derby school (St Andrew’s Academy) and their students to experience the design and manufacture of items. The one you can see in the image is a small table ready for their campus.

We’re impressed with our small but mighty CNC router so far!

Full of hot air

On a recent day trip Craig saw some hot air balloons and was fascinated by them operationally. Here’s some interesting facts he found (in his own time!) about these interesting contraptions:

- Hot air balloons can’t be used in the rain as the rainwater cools the balloon, meaning more heat is needed, and it adds additional weight to the balloon

- Hot air ballooning dates back to the late 18th century. The Montgolfier brothers, Joseph-Michel and Jacques-Étienne, are credited with launching the first untethered hot air balloon flight in 1783

- The principle behind hot air ballooning is simple yet fascinating. When air inside the balloon envelope is heated, it becomes less dense than the surrounding air, causing the balloon to rise. Propane burners are used to heat the air inside the balloon, allowing it to achieve the necessary lift. The amount of lift generated is directly related to the temperature difference between the heated air and the ambient air.

Oh and the final fact? There wasn’t a hot air balloon in the ‘Around the World in 80 Days’ novel by Jules Verne; it was added for dramatic effect in the 1956 film.

The real question is – would you get into one and take a flight? Craig’s not so sure he would! Seleena is up for a hot air balloon flight….

Start the conversation

Seleena has a new ‘mug’ but Craig has decided she is not allowed to take it into the workshop. There doesn’t need to be any confusion between what we are spraying and drinking!

If you’ve got a project in the pipeline that you’d like to discuss with the team we’d be delighted to hear from you (info@beneng.co.uk or 01332 419220)

As a reminder our services include:

- Design for manufacture

- Machinery makers and maintenance mates for manufacturers:

- Bespoke machinery

- Bespoke platforms, lifting jigs, stairways

- Machine modernisation

- Assembly services for existing sub-assemblies / machinery / equipment as your overflow / expert partner