Ageing Pump Asset Modernisation for a Major Utility Supplier

The Benefits:

Pump assets will be capable of another 20 years’ service.

Deritend were able to gain the refurbishment contact from its utility supplier for all eight pumps thanks to the successful modernisation of the first.

Improved hydraulic efficiency means that a single pump is now used where previously it was almost a full time job for two.

Concise documentation enables the easy identification of replacement parts.

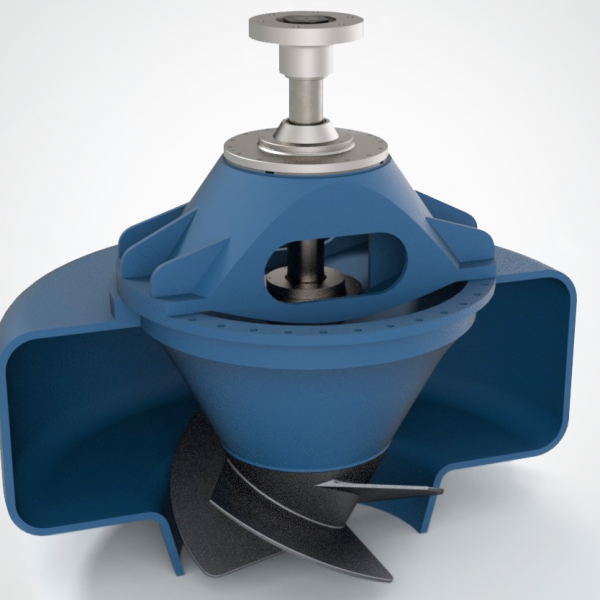

The Deritend Group, a leading supplier of engineered solutions to industry specialising in pump repair and refurbishment, approached Bennett Engineering Design Solutions in 2012. Its client, a major UK utilities supplier, required a total of eight 60 year old Dry Well storm pumps to be modernised, a project that required highly specialised machine modernisation expertise.

John Bennett, Director, Bennett Engineering Design Solution, explains: “In-depth discussions with Deritend proved that we had the necessary experience in pump design and crucially, we were able to foresee the pitfalls associated with this rigorous challenge. It was agreed that initially we would work on a single pump before approval from their client could be gained for work to begin on all eight.”

The scope of the challenge involved re-engineering the pump’s existing 60 year-old white metal thrust bearing, which meant new bearing thrust calculations for a set of bearings with an asset life of 20 years.

The Problem:

The existing metal thrust bearings were a special type of plain bearing which required a constant supply of clean oil to be fed to them under pressure. The oil supply, seals and hoses were all prone to failure however. This had led to the bearings destroying themselves and the potential for oil to contaminate the water. The components for the bearing were also no longer available and although it was possible to get them made, all of the other issues meant that modernising the pumps was a far better option.

The Solution:

The team worked closely with a Deritend engineer who took the pump apart so that he could understand better where the problems may lie. This expert hands-on approach helped to ensure the successful modernisation of the first pump.

John Bennett explains: “We tried to reuse or modify everything from the original pump. It was impossible however, to fit modern bearings without designing new housings for them. Sometimes we could adapt the existing main shaft, but often we had to design new ones. This all required highly detailed knowledge of pumps, shaft design and machining tolerances.

The team met Deritend’s specifications by developing simple designs that were cost effective to make. This included a 3D SolidWorks model and a full set of new component drawings to assist the re-engineering of the existing assets. This meant that when the parts were finally manufactured and assembled by Deritend, they all fitted together correctly the first time around. Deritend were also able to explain to their client the true scale of the project thanks to the 3D model.

Increased hydraulic efficiency

The new bearing and seals absorb less energy compared with the originals, this together with the abrasive resistance efficiency coating which Deritend applied to the surfaces in contact with the water, meant the pumps were able to pass more water after the refurbishment. The modern bearings have a much longer life, are very reliable and require little maintenance. While the new split mechanical seals don’t need adjusting therefore, they do not leak.

John Bennett explains: “Mechanically, the utility supplier gained increased hydraulic efficiency from their pumps and of course, improved reliability and pump availability. As part of our commitment to increasing operational efficiency and reducing operating costs, the client benefited from both reduced maintenance costs and total cost of ownership. Ultimately though, they have eliminated the risk of environmental pollution incidents from these ageing pump assets.”